Industrial Shredding Machine Manufacturers in Mumbai

What is an industrial shredding machine?

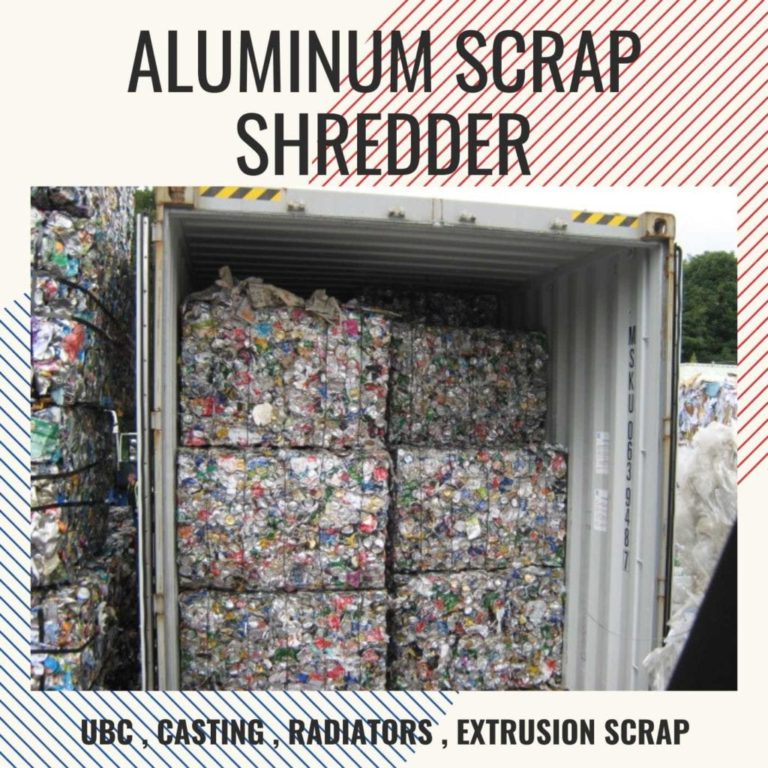

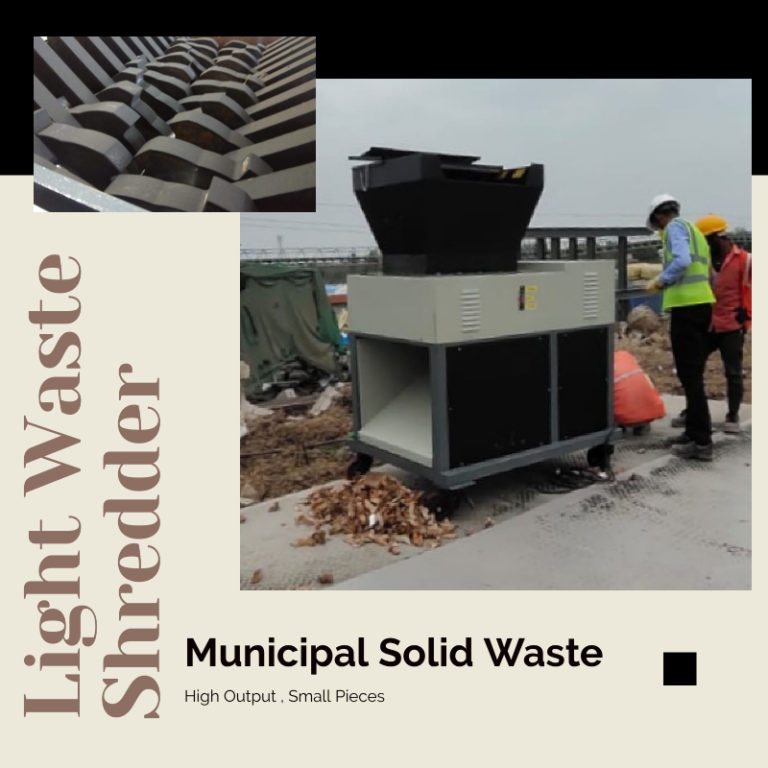

Industrial shredding machine is a piece of heavy duty equipment available for roughly reducing big size industrial waste/scrap material into smaller sizes. Normally this machine is prior to granulating or other further handling process. With the increase of environmental protection consciousness and development of recycling industry, shredding machine now plays an important role in many applications. For example, paper, cardboard, biomass, wood, tire, plastic, metal, textile etc.

What are the different types of industrial shredding machine ?

Categorized by the different types of cutting systems adopted, there are single shaft shredding machine, double shaft shredding machine and four shaft shredding machine available.

Industrial single shaft shredder

Single Shaft Shredding Machine also popular as Single Rotor Shredding Machine, is equipped with one high-speed cutting rotor and a hydraulic driven horizontal pusher for pushing material close to the cutting rotor for efficient shredding. It is versatile shredding equipment suitable for processing a wide range of materials to a uniform particle size. A replaceable screen is mounted underneath the cutting rotor. Various sized screens are available for you to conveniently control the shredded particle size to fit your specific needs.

Industrial double shaft shredder

Double Shaft Shredding machine also popular as Dual Shear Shredding machine or Twin/Double Shaft Shredding machine, employs two counter rotary cutting shafts that rotate into each other at low speed under high torque. There are hooks on the shear blades which grab the fed-in material,

and then along with the rotation movement, the blades cut, shear, tear, slice and rip apart a variety of materials into smaller pieces. This type of shredding equipment generally has no sizing screens. The output particles are typically in strips. Each cutting blade’s thickness which is customizable determines final particles’ width directly. So this twin shaft shredding machine is usually available in bulky item reduction, product destruction or primary shredding where requires particle size variation.

Common features of single shaft shredder and double shaft shredder

Both Single Rotor Shredding machine and Dual Shear Shredding machine feature PLC control system and automatic reverse rotation. The auto reverse functions any time in case of excessive quantities to shred or material that cannot be shred, cutters stop operating and automatically rotates in reverse direction to free up any jam. And once jam is discharged, shredding machine will automatically resume normal shredding operation. This auto reverse not only protects machine itself from overloading and breaking, but also guarantees a continuous and streamlined shredding operation.

Industrial shredding machine from Shredders and Shredding

Shredders and Shredding offers various types of size reduction machines with a wide choice of different cutting knives, screen mesh sizes and output capacity to meet your specific requirement. Our team is always ready to help you choose the best suited model for your needs. Contact us now to get an optimal solution for your project.

Please Contact Us We Will Guide You to the Best industrial shredding machine as per Your Need :

Call or WhatsApp: +91 9820020714

Can Also Check Our Factory other shredders

You can also contact us on this site : papershredders.co.in