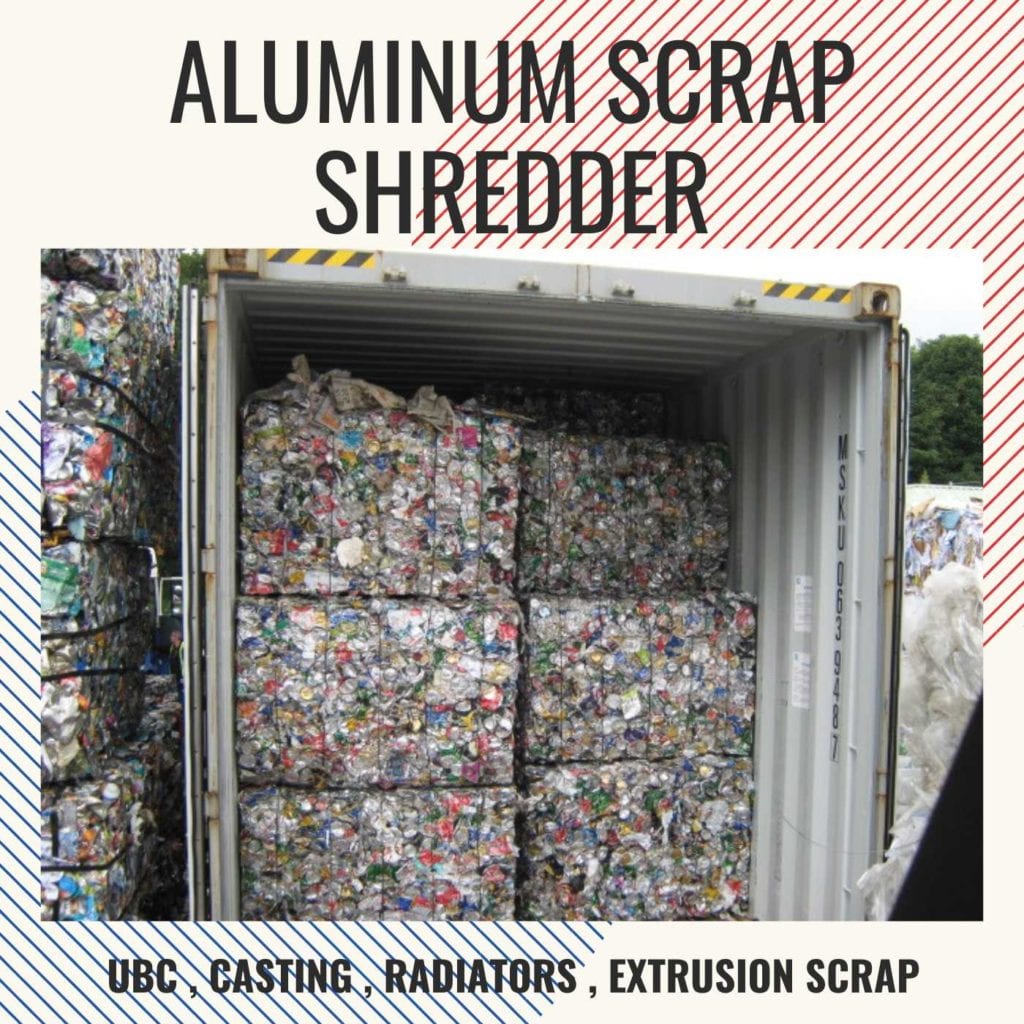

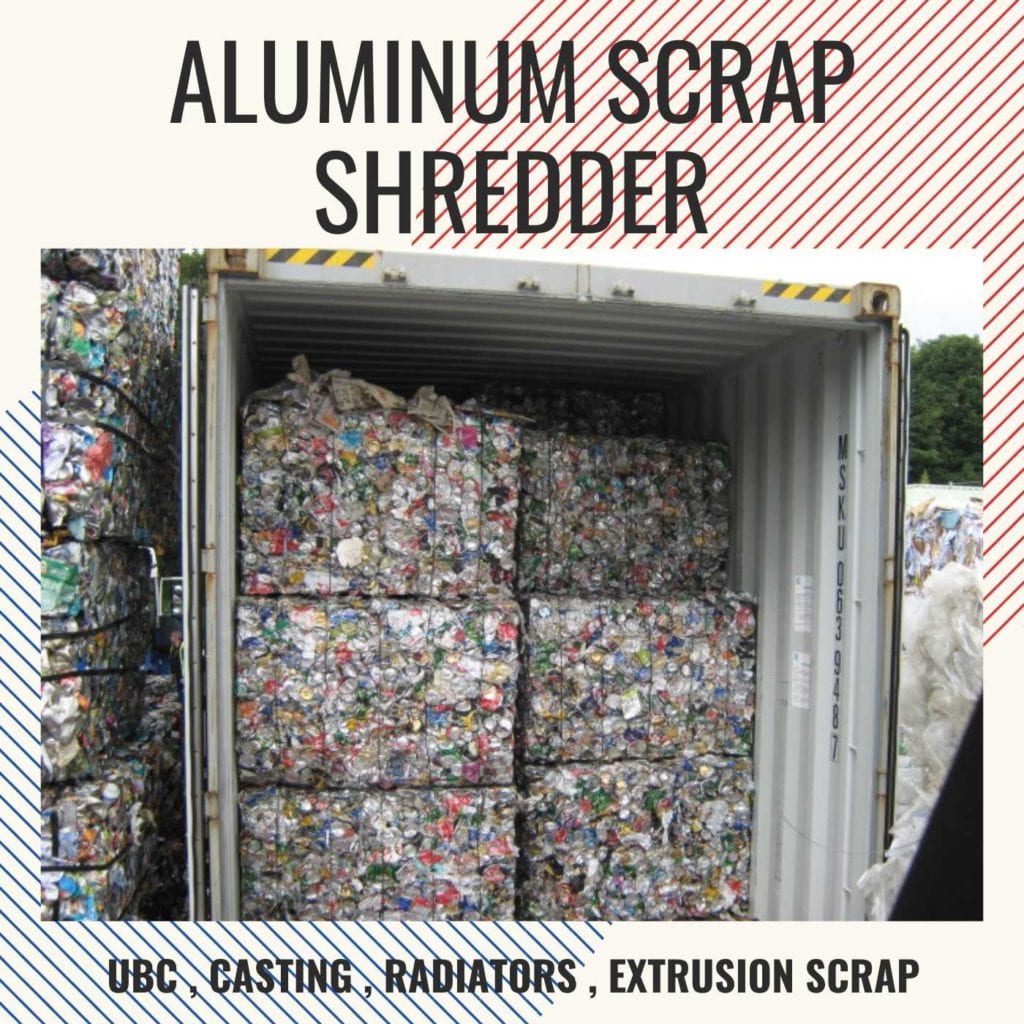

Heavy-duty industrial aluminium cans shredding machine

The Imported UBC bales are tightly compacted, a problem in India regarding recycling. Our PROKATO Heavy-duty industrial aluminium cans shredding machine not only loosens the bundle but also breaks them into smaller pieces.

The paintings and coatings used for decoration and protection purposes are easier to get rid of this way. Additionally, it makes it easier for the metal to melt quickly in the furnace.

The Shredded Cans are Passed under a Powerful Magnet

This process aims at eliminating traces of steel. The aluminium and steel are separated by passing them under a magnet. This ensures that the recycled aluminium contains no steel and meets the quality standards set.

De-coating

A conveyor system then takes the aluminium shreds into a specialized decoater. This is where all the shredded pieces get rid of the decorations. The decoater then blows very hot air through the tiny pieces of shreds and the coatings, paintings and inks vaporize.

The De-coated Shreds Are Then Fed Into the Furnace

The furnace temperature is usually 700 deg celsius. This is the lowest melting point for certain metals. Certain chemicals are added into the molten aluminium to correct the composition. All the impurities will then float to the top surface of the hot aluminium. This forms a layer called dross. A specialized scraping tool then removes the dross.

The Holding Furnace

The molten aluminium is transferred to the holding furnace where it is turned into ingots. From time to time, the holding furnace tilts to pour the molten aluminium into moulds. Each ingot or block contains approximately 1.6 million drink cans.

Transportation of the Ingots

The ingots again are the raw materials to make thin sheets of aluminium to make drink cans, foils and other useful products. The recycled aluminium products are sent back to the shelves in the shops and supermarkets in just 6 weeks!

Did you know the world leader in rolled aluminum products and recycling, and the largest global producer of automotive and beverage can sheet is an INDIAN company?

One of the top subsidiaries of Hindalco Industries Limited is Novelis. They are an industry leader in aluminium and copper and the metals flagship company of the Aditya Birla Group, a multinational conglomerate based in Mumbai, India.

We make these large double shaft Heavy-duty industrial aluminium cans shredding machine for recycling companies as well as SMALL CAN SHREDDER for commonplace use or home society use. This can be your part in recycling the waste and setting it on the path of proper recycling.

CONTACT US to know more: +919820020754