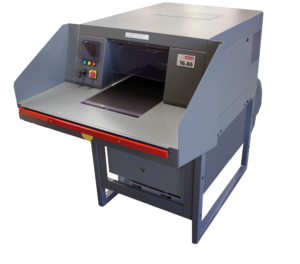

intimus 16.86

HIGH-VOLUME INDUSTRIAL SHREDDER BALER COMBINATION

The Intimus 16.86 High-Volume Industrial Shredder Baler is the ultimate solution for businesses needing secure, large-scale document destruction and waste management. This powerful shredder-baler combination efficiently shreds high volumes of paper and compresses them into compact bales, simplifying disposal and reducing waste space. Ideal for industries, government institutions, and organizations with demanding shredding needs, the Intimus 16.86 delivers robust performance and convenience in one machine. Shredders and Shredding Company (SASCO) is a leading manufacturer of industrial shredders and the authorized distributor of Intimus products, supplying the 16.86 Shredder Baler across India and worldwide at unbeatable prices.

Industrial Usage

P-2 | Heavy duty shredder engineered for high-performance in centralized applications, equipped with an integrated conveyor belt and baling press. It effortlessly handles up to 450 sheets simultaneously, delivering an impressive throughput of approx. 550 kg/h.

Shredding material:

- Paper with staples and paper clips

- Crumpled paper

- CD / DVD / Blu-ray

- Plastic card

- Folder

- Floppy disk

Please Contact Us We Will Guide You to the Best Paper Shredder as per Your Need

Call or WhatsApp: +91 9090003535

The intimus 16.86 SmartShred stands out as a robust, heavy-duty document shredder featuring a feed conveyor belt. It efficiently shreds and compacts materials into bales simultaneously. Equipped with a user-friendly touchscreen and programmable logic controller (PLC), it offers various functionalities such as language selection, recording of operating hours, display of machine processes, precise error reporting, and maintenance reminders, streamlining maintenance procedures. Emergency stop bar ensures operators´ safety in case of emergency.

With its broad 500 mm working width, it facilitates convenient and rapid loading, effectively shredding all types of paper materials including loose, stapled, bound, crumpled, and even entire folders. It also accommodates small quantities of plastic materials like credit cards, CDs, and floppy disks. Meeting security level P-2 standards with a cutting width of 10 x 70 mm, it ensures data security.

An auto-reverse function swiftly clears paper jams caused by overloading. To retrieve bales, a push-button control is provided, initiating the compaction process automatically. An indicator signaling “Bale complete” halts the cutting process, and double strapping guarantees bale stability. Standard features include an intelligent automatic oiler, enhancing operational efficiency and prolonging equipment lifespan.

Key Features

- The particles, measuring 10 x 70 mm, conform to security standard P-2 as per DIN 66399 (ISO/IEC 21964).

- Compatible with various paper materials including loose, stapled, bound, or crumpled, as well as entire folders and small quantities of plastic materials such as credit cards, CDs, and floppy disks.

- Efficiently processes 400-450 sheets of 80 g/m² paper with a working width of 500 mm, ensuring rapid and effective document processing.

- Ensures smooth operation with a high throughput of approx. 550 kg per hour.

- Comes equipped with a sturdy metal housing.

- The shredded material is compacted into bales to reduce its volume by up to 70%.

- Induction-hardened, nitrocarburised solid steel cutting cylinders/shafts guarantee durability and an extended service life.

- Features an intuitive touch display with programmable logic control (PLC).

- Includes emergency stop bar, emergency stop switch and lockable main switch for added safety.

- Facilitates effortless document shredding with high-capacity conveyor belt, automatic return, overload protection and automatic oiler.

Specifications

| Area of application | Industrial |

| Cutting size paper (mm x mm) | 10 x 70 |

| Cutting type paper | Cross cut |

| Security level ISO/IEC 21964 (DIN 66399) | P-2 / O-2 / T-21 / E-23 |

| Shredding material | Paper with staples and paper clips, Crumpled paper, CD / DVD / Blu-ray, Plastic card, Folder, Floppy disk |

| Material cutting cylinders / shaft | Induction-hardened, nitrocarburized solid steel |

| Waste disposal solution | Bale press |

| Intake width (mm) | 500 |

| Inlet / desk height (mm) | 1.200 |

| Sheet capacity (80g/m²) | 400 – 450 |

| Throughput | approx. 550 kg/h |

| Cutting speed (80g/m²) mm/s | 240 |

| Continuous Running | yes |

| Noise level (idle operation) dB(A) | 61 |

| Motor protection device with thermal sensor | yes |

| Power supply (V / Hz) | 400 / 50 |

| Other voltages available | yes |

| Product dimensions W x D x H (cm) | 121 x 284 x 163 |

| Product weight (kg) | 1.256 |

| Control operation | Touch display |

| Visual status indication for … | All activities and issues are shown on display and information e.g. overall operation time, blockages |

| Auto reverse | yes |

| Internal conveyor belt | yes |

| Hour meter | yes |

| Overload protection | yes |

| Safety features | Emergency stop bar, Transparent plastic curtain in feeding area |

| Lockable master switch | yes |

| Dust extractor | yes |

| Castors | Baler |

| Parking brakes | yes |

| Material machine housing | Metal |

| Made in Germany | yes |

| Certificates / Listings | CE, UKCA |

| Bale press | yes |

| Press force of baler (kN) | 80 |

| Bale weight (kg) | 60 – 80 |

3 Only plastic cards with electronic chip.

Download DataSheet

Video

Intimus 16.86 High-Volume Industrial Shredder Baler - Shredders and Shredding Company

The Intimus 16.86 High-Volume Industrial Shredder Baler is the ultimate solution for businesses needing secure, large-scale document destruction and waste management.

Product Brand: INTIMUS

Product Currency: INR

Product Price: 1800000

Product In-Stock: InStock

5