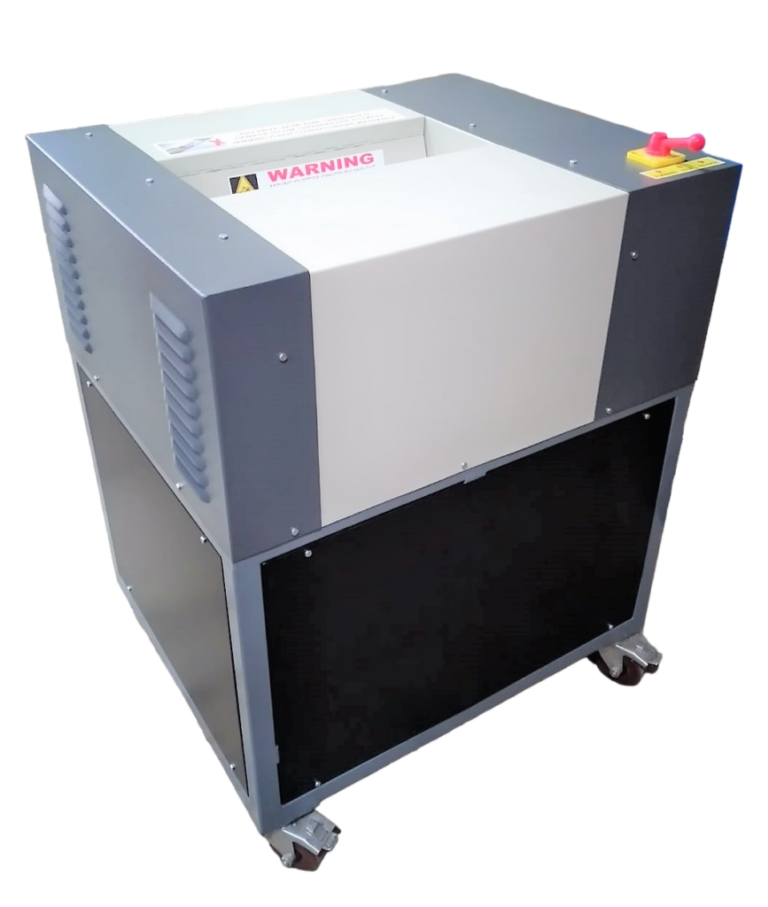

Intimus 16.99

INDUSTRIAL SHREDDING SYSTEM

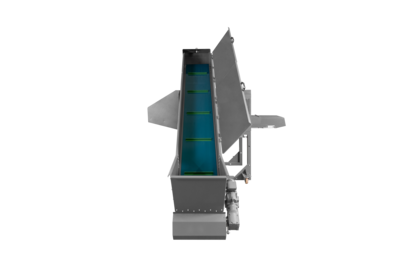

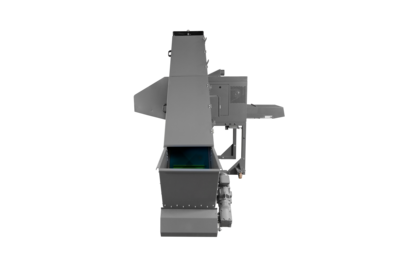

The Intimus 16.99 Industrial Shredding System is an advanced high-capacity shredder designed to handle heavy-duty industrial shredding needs with ease. Capable of processing up to 550 kg per hour, this system features an automatic lateral conveyor belt and horizontal discharge conveyor, streamlining the shredding process for maximum efficiency. Equipped with a baler and mobile collection container, it ensures that shredded material is efficiently compacted and easy to manage, making it perfect for high-volume environments like manufacturing facilities and secure disposal services. Shredders and Shredding Company (SASCO), a leading manufacturer and authorized Intimus distributor, supplies the 16.99 Industrial Shredding System and Own Manufacturing Industrial Shredding System across India and worldwide, offering unmatched prices on reliable, top-tier shredding solutions.

Industrial Usage

P-2 | High capacity shredder with automatic lateral conveyor belt and horizontal discharge conveyor, baler, and mobile collection container, handling up to 550 kg/h.

Shredding material:

- Paper with staples and paper clips

- Crumpled paper

- CD / DVD / Blu-ray

- Plastic card

- Folder

- Book

- Floppy disk

Please Contact Us We Will Guide You to the Best Paper Shredder as per Your Need

Call or WhatsApp: +91 9090003535

For many decades, the Intimus 16.99 SmartShred series has proven itself for data protection-compliant document disposal. This centrally positioned large shredder system with automatic conveyor belt feed enables fast and secure destruction through controlled, automated and secure feeding of the data carriers. Thanks to an intelligent PLC control system, the shredder can be optimally customised to the customer’s needs and is easy to operate. The model range offers various options for material discharge, such as a baling press for fully automatic compaction of the shredded material, discharge conveyors or other waste disposal solutions. We also offer customised solutions according to your individual requirements.

Key Features

- User-friendly operation is ensured by a clear control panel equipped with a safety concept and security device.

- The SmartShred programmable logic controller (PLC) facilitates various functionalities such as logging of operating time, precise error display, and maintenance reminders, thereby expediting maintenance tasks.

- The induction-hardened cutting cylinders made of high-quality steel can even destroy complete file folders without loss in cutting performance, ensuring a prolonged service life.

- High performance is achieved through efficient and continuous document feeding via an automatic lateral feeding conveyor belt.

- A broad emergency stop bar ensures immediate machine shutdown in case of danger.

- The powerful geared motor, thermally protected and boasting 7,5 kW drive power, guarantees smooth continuous operation.

- Data destruction is securely executed in security level P-2 according to DIN 66399.

- In the event of overload, both the cutting unit and conveyor belt automatically reverse and then switch back to forward running after a period of time.

- An integrated automatic lubricator ensures consistent high cutting performance and quality.

- Utilizing a baler, the shredded material is promptly compressed into compact bales weighing between 60 to 80 kg, all done fully automatically. This offers the advantage of reducing the volume of the shredded material by approximately 70% compared to loose collection.

- Optional suction system available.

- Completely integrated into the shredder’s control system, the feeding conveyor belt, equipped with cleats, guarantees uninterrupted feeding and consistent material flow.

- Its robust steel construction and 2-layer PVC belt ensure long-term durability.

- With a belt speed of 5.64 m/min and a cover on both sides it provides a high level of security and protection against unauthorized access.

- Additionally, the feeding conveyor belt offers the flexibility to be mounted on either the right or left side.

Specifications

| Area of application | Industrial |

| Cutting size paper (mm x mm) | 10 x 70 |

| Cutting type paper | Cross cut |

| Security level ISO/IEC 21964 (DIN 66399) | P-2 / O-2 / T-21 / E-23 |

| Shredding material | Paper with staples and paper clips, Crumpled paper, CD / DVD / Blu-ray, Plastic card, Folder, Book, Floppy disk |

| Waste disposal solution | Bale press |

| Intake width (mm) | 500 |

| Inlet / desk height (mm) | 1.200 |

| Sheet capacity (80g/m²) | 400 – 450 |

| Throughput | up to 550 kg/h |

| Cutting speed (80g/m²) mm/s | 240 |

| Continuous Running | yes |

| Noise level (idle operation) dB(A) | 61 |

| Motor protection device with thermal sensor | yes |

| Power supply (V / Hz) | 400 / 50 |

| Other voltages available | yes |

| Product dimensions W x D x H (cm) | 378 x 283 x 235 |

| Control operation | Touch display |

| Visual status indication for … | All activities and issues are shown on display and information e.g. overall operation time, blockages |

| Auto reverse | yes |

| Internal conveyor belt | yes |

| External lateral conveyor belt | yes |

| Hour meter | yes |

| Overload protection | yes |

| Safety features | Emergency stop bar, Transparent plastic curtain in feeding area |

| Lockable master switch | yes |

| Dust extractor | yes |

| Expansion of feed table | yes |

| Castors | Shredder |

| Parking brakes | yes |

| Material machine housing | Metal |

| Made in Germany | yes |

| Certificates / Listings | CE, UKCA |

| Bale press | yes |

| Press force of baler (kN) | 80 |

| Bale weight (kg) | 60 – 80 |

3 Only plastic cards with electronic chip.

Download DataSheet

Video

intimus 16.99 INDUSTRIAL SHREDDING SYSTEM - Shredders and Shredding Company

The Intimus 16.99 Industrial Shredding System is an advanced high-capacity shredder designed to handle heavy-duty industrial shredding needs with ease.

Product Brand: INTIMUS

Product Currency: INR

Product Price: 2500000

Product In-Stock: InStock

5