Industrial shredder machine for metal and hard items

Consider our industrial shredder machine if you need an economical yet durable shredder for your business, tell us what you want to shred and we will suggest the best option. So that you can focus on your main business and trust us with the shredding equipment performance !

Our PROKATO™ Industrial shredder machine range is designed and manufactured in INDIA for heavy non-stop use –

- Destroying and protecting waste materials from the misuse (safe to dispose of as per norms)

- Reducing volumes saving transportation and storage costs (proper waste management)

- Processing material for production (breaking bigger into smaller pieces for greater efficiency)

No matter for what purpose you want an industrial shredder machine, we offer customized solutions for your application. The design of these machines is according to the material, the throughput required and finally the purpose of shredding.

The Design

We make our SMALL / MEDIUM and LARGE range of industrial shredder machine with cutters of wear-resistant high-quality tool steel, hardened, sharpened and guaranteed to last longer than ordinary materials. Putting the best available material in our machines, sourcing from the best OEM is just not a matter of quality for us but we know no other way of engineering world-class machines for our customers.

SMALL

P2

Multi purpose shredder machine for lite use

The machine can be used as a stand alone unit as well as coupled with other processing machines

Cutting Chamber : 250 x 210 mm

Power : 1.57kW / 2hp

Output : 50 Kgs / Hour

P3

Medium duty with good strength to break semi hard materials

This machine is compact, silent yet powerful model, some materials that cannot be shredded in the smallest model can easily be destroyed in this machine

Shredder Opening : 300 x 240 mm

Power : 2.2kW / 3hp

Output : 100 Kgs / Hour

P5

Powerful and with a bigger opening for crushing bulky materials

This shredder has the biggest opening and powerful gearbox, if you need a shredder for commercial applications this is the best bet

Shredder Opening : 450 x 300 mm

Power : 3.7 kW / 5hp

Output – 150 Kgs / Hour

MEDIUM

P7

Cutting Chamber : 540 x 380 mm

Power : 5.5 kW / 7.5 hp

Output : 250 Kgs / Hour

P10

Cutting Chamber : 600 x 400 mm

Power : 7.5 kW / 10 hp

Output : 300 Kgs / Hour

P15

Cutting Chamber : 700 x 500 mm

Power : 11 kW / 15 hp

Output : 500 Kgs / Hour

Some of our common models.

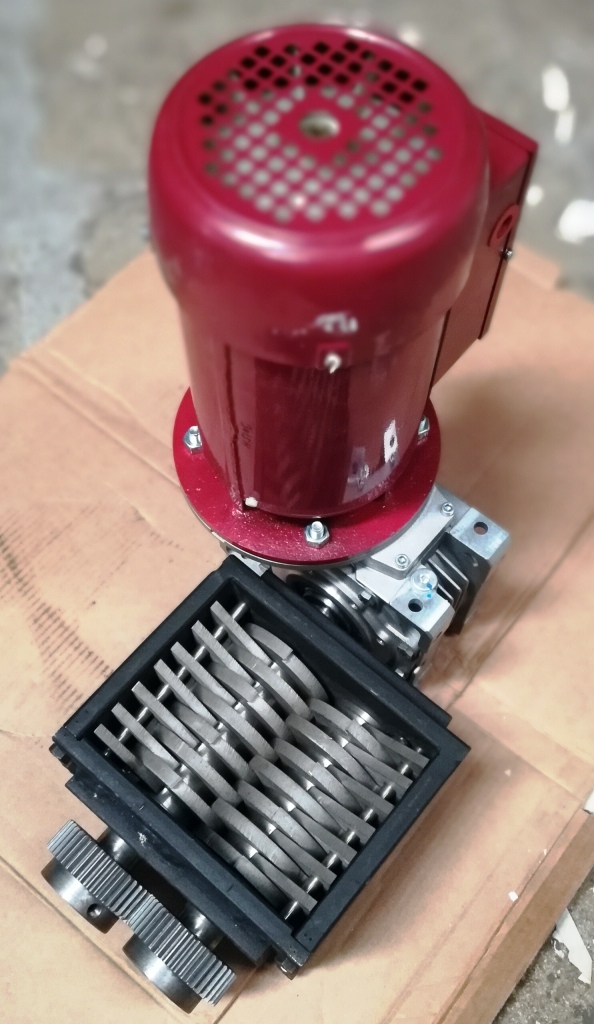

Model P3 – Small Multi Shredder

This compact small industrial shredder machine (available in three sizes) can destroy – Hospital waste, Laboratory Waste, Optical media like CD’s, Hard disks, cassettes, occupies very little space and is silent yet powerful, ideal for indoor use and for destroying small quantities and small-sized materials.

- Cutting Chamber :110X240mm / 200X240mm / 300X240mm

- Motor: 2.2kW/3.0kW

- Throughput/Hour: 50 – 100 Kgs.

- Weight of shredder head: 180 kgs

Model P5 – Mid sized shredder

This mid-sized shredder machine (available in two variations) can destroy – light materials like mobile phones, cassettes, factory packaging, plastic carcasses of electronic devices, food/kitchen waste, garden waste Etc. Fitting on a stand with wheels is also an option for easy movement.

- Cutting Chamber :200X300mm / 300X300mm

- Motor: 3.7 kW

- Throughput/Hour: 100 – 200 Kgs.

- Weight of shredder head: 275 kgs

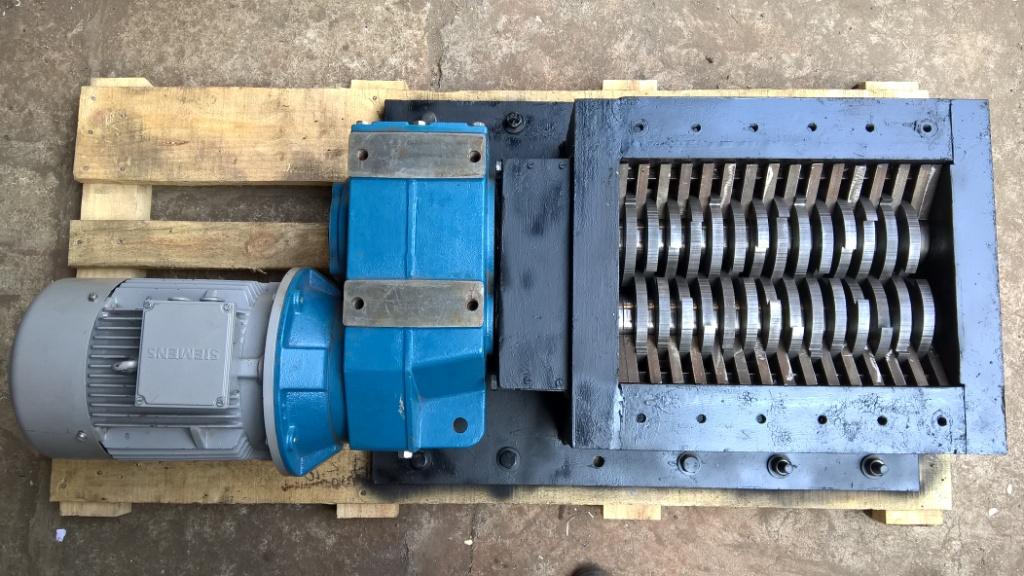

Model P10 – The Crusher

Shredder Opening -600x400mm

Drive – 10HP (Three Phase)

Throughput – 300 Kgs/Hr

Weight of the Machine – 525 Kgs

MODEL SMSZ 10

You can shred lightweight materials, aerosol cans, production scrap, in the recycling industry for pre-processing of raw material. This industrial shredder machine can handle anything you throw at it.

- Cutting Chamber : 3 sizes, Viz: 360X380mm / 500X380mm / 600X380mm

- Motor : 5.5kW / 7.5 kW

- Throughput/hour : 50 – 150 kgs / 150 – 250 kgs

- Weight of shredder head: 650/750 kgs.

MODEL SMBZ 10 –

Is an industrial shredder with a Large-sized opening a horizontal conveyor feed industrial shredder machine for the printing and packaging industry. It can cut – Cardboard’s, Papers with file clips, CDs, Aluminum foils, films, PVC packaging material, Corrugated cartons, Old Office Documents

- Cutting Chamber : 3 sizes, Viz: 430mm / 510mm / 730mm

- Motor : 3.7 kW / 5.5 kW / 7.5 kW

- Throughput/hour : 500 – 2500 kgs

- Weight of shredder head: 550 kgs.

MODEL smSz 15 –

This shredding machine is for large volume but light industrial scrap, foodstuff, food waste, linen, papers

- Cutting Chamber : 2 sizes, Viz: 650X440mm / 800X440mm

- Motor: 11 kW

- Throughput/hour : 250 – 400 kgs

- Weight of shredder head: 1500 kgs.

MODEL smSz 25 –

This Powerful industrial shredder machine can just about destroy anything! Large volume industrial scrap including wood, Pre-process of hard plastics for recycling, Non-ferrous Metals – Aluminium, copper brass

- Cutting Chamber : 2 sizes, Viz: 650X540mm / 1050X540mm

- Motor : 18.5 kW / 22 kW

- Throughput/hour : 500 – 1000 kgs

- Weight of shredder head: 3000 kgs.

MODEL smSz 50 –

Our Biggest machine for large volume industrial scrap, generally used for recycling, car tires, large and hard materials, entire units can be put directly into the shredder!

- Cutting Chamber : 1100X750mm

- Motor : 37 kW

- Throughput/hour : 1000-2000 kgs

- Weight of shredder head : 5500 kgs.

SPECIAL INDUSTRIAL SHREDDER – Customized machines

Shredder for Moist Material made in SS for food waste, contaminated BMW, MSW, Organic waste, ampules, vials and other pharma waste.

- Cutting Chamber : 650X440mm

- Motor: 7.5kW

- Throughput/hour : 500 kgs

- Weight of shredder head: 1550 kgs.

Single shaft shredder available in three sizes with screen to break lumps into smaller pieces

- Cutting Chamber : 360X380mm/500X380mm/600X380mm

- Motor: 5.5kW/7.5kW

- Screen : 10 – 40mm

- Throughput/hour : 50-150 kgs / 150-250kgs

- Weight of shredder head: 650/750 kgs.

This single shaft machine is useful for breaking lumps of materials for recycling

- Cutting Chamber: 600X390mm

- Motor: 7.5kW

- Screen : 10 – 40 mm

- Throughput/hour: depending on the material

- Weight of shredder head: 700 kgs.

In any case, your investment should pay off and you should get the complete value of money from these industrial shredder purchase. For this, our complete understanding is important so we can suggest the most appropriate machine. This is where our experience is valued most.

Why choose our machine?

Often this is not an easy task given the variety of industrial shredder machine for sale available thus the right choice of machine most ideal for your use is to be carefully selected.

We would happily help you with our experience. We have a few differently configured industrial shredder for sample tests available at our facility and encourage customers to send samples for first-hand result inspection and verification.

As far as we know, no shredder can process everything. More often than not, the desired result can only be achieved by tailor-made technology that we can give you. And of course, for us, anything can be shredded!

Click here to know more about industrial shredder that will work for you. You may even fill the contact form or call us for help and advice anytime!

Call (+919820020754) to know more about how you can save a lot of money and how our machines can be useful to you. We shall be glad to meet you and advise the best solution.

Why our INDUSTRIAL SHREDDER IS SPECIAL

| We use the best metals and our powerful drives are factory synced matched Tried and Tested thoroughly before dispatch |

| If you bought a INDUSTRIAL SHREDDING SYSTEM from us, you can rest assured that the components, motor and control panel, VFD or SCR drive is a perfect match. At our factory, we pair each shredder motor with its drive system and thoroughly test the performance and every operating parameter under maximum load, The motor and drive are fine-tuned to deliver trustworthy performance before they leave our factory. We ensure they are ready to operate at your site after extensive trials before the shredder leaves our factory, with all adjustment in settings to work with the other components and integrations done before dispatch itself. We ensure that our customers get exceptional value for money with our industrial shredder machine to give a perfectly scyncronised system giving you the best possible performance day in and day out. All SASCO new shredder built either stand alone machines or integrated systems are fine tuned to perform consistently from day one and continue for many man hours without any trials and errors. |

Disclaimer – Similar sounding names are not associated with us in any manner, please remember us as SASCO. We use all actual unedited pictures of our machines. We can make stands, hoppers, Waste Bins, Control panels all per customer requests.